Southwest

Environmental Limited

Southwest

Environmental Limited Southwest

Environmental Limited

Southwest

Environmental Limited| London |

| 02076 920 670 |

| Exeter |

| 01392 927 961 |

| Manchester |

| 01612 970 026 |

| Bristol |

| 01173 270 092 |

As well as offering factual reporting SWEL can

also offer interpretive reports, offering advice on Foundation

Design, Building on Made Ground (RQA) , Building Near Trees and other common

geotechnical problems. We also pride ourselves on a quick turn-around

and overcoming obstacles ourselves where possible, meaning we are a low

effort (hassle free) option to take if you require geotechnical

engineering input.

Tip: This is a large page please use "Control + F" to

find what you are looking for.

Design of foundations is not only crucial

to the stability of proposed structures, it is also a

significant portion of the building costs.

Design of foundations is not only crucial

to the stability of proposed structures, it is also a

significant portion of the building costs.

At SWEL we can design foundations to

ensure a good compromise between cost and stability, many firms

will limit risks to themselves by over specifying foundations.

You will not find that attitude at SWEL.

Related Services: Geotechnical

Investigation

| How do geotechnical engineers assess rock strength? |

| Geotechnical

Design Standards HD 22 |

| Types of Drilling Rig |

| Pile design based on geotechnical parameters. |

| Geotechnical

Certificates |

| If I am building near trees are there any special precautions? |

|

Geotechnical Design Standards EN 1997-1:2004 (Eurocode 7) |

| Geotechnical Considerations of Building Aggressive Ground |

Geologists have been studying the ground for a hundred plus years, and over time have built up a system for quantifying soil strength it is based on shear strength, and although this is most accurately measured in a geotechnical laboratory, there are numerous ways a geotechnical engineer can measure these strengths in the field, to obtain an immediate and fairly accurate (some may argue more accurate) measure of strength.

One method uses the human hand, and involves squashing poking the soil to give an idea of strength as the table below shows. There are also various basic tools that can be used such as a hand vane and pocket penetrometer.

It is also possible to use a testing hammer on a drilling rig to assess in-situ strengths (Stroud 1989).

Shear Strength |

Field Identification |

Hand Vane |

Pocket Penetrometer |

| <20 (Very Soft) | Squishes out between fingers when

squeezed in hand. Can poke finger 25mm in to soil easily. Will not keep its own shape, it slumps when placed on surface. |

<20 | <0.4 |

| 20 - 40 (Soft) | Can be squashed in to shapes with

light pressure. Finger can be pushed in 100mm or so. Will just keep it shape when placed on a hard surface, slight slump. |

20 - 40 | 0.4 - 0.8 |

| 40 - 75 (Firm) | Can be molded

with strong finger pressure. |

40 - 75 | 0.8 - 1.5 |

| 75 - 150 (Stiff) | Cannot be molded by

fingers. Can be indented slightly with thumb. |

75 - 150 | 1.5 - 3.0 |

| 150 - 300 (Very Stiff) | Can be indented by thumb nail, but not thumb. |

>150 | >3.0 |

| 300< (Hard) | Normally Brittle. Cannot be indented by thumb nail. |

NA | NA |

In situ tests for granular soils are particularly important as once they have been "dug" up it is hard to tell how strong they are without laboratory testing.

Cohesive |

Granular |

||

| Description | N - Value | Description | N - Value |

| Very Soft | <4 | Very Loose | 0 - 4 |

| Soft | 4 - 8 | Loose | 4 - 10 |

| Firm | 8 - 15 | Medium Dense | 10 - 30 |

| Stiff | 15 - 30 | Dense | 30 - 50 |

| Hard | 30 < | Very Dense | 50 + |

Trees need water to grow, the roots in the soil suck up

water and this effects the properties of the soil.

Trees need water to grow, the roots in the soil suck up

water and this effects the properties of the soil.

Desiccation of soil from trees is particularly

noticeable in clays with a high shrinking/swelling potential. As

the water is removed from the soil it shrinks which can lead to

settlement that may damage buildings.

Conversely is a tree is removed from site shortly

before construction starts soil that has been artificially

desiccated by trees can swell or heave again causing damage to

buildings.

Geotechnical Consultants can offer advice on

building

near trees in line with NHBC guidelines. <Click this link

for more information on building near trees.

Rock strength is assed in a number of ways, there are empirical methods based on hits clasts of rock with hammers, and there are measured methods such as in-situ testing and laboratory testing.

Some may call empirical methods estimates, but in truth when carried out by an experienced geotechnical engineer they are surprisingly accurate.

In weaker or highly fragmented rocks the good old SPT can be used to assess strength. CBR tests are also useful.

A point load test is sometimes useful , for giving an accurate gauge of rock strength.

However, all of the above methods should be used with caution, as they give a rock clast strength, for the design of foundations the really important strength value is the Rock Mass strength. For example, a highly fractured rock mass (such as you might find in northern Bristol) with in filled fractures will behave similarly to a soil in some instances. Particularly where point loading occurs with piled foundations for example this should not be overlooked.

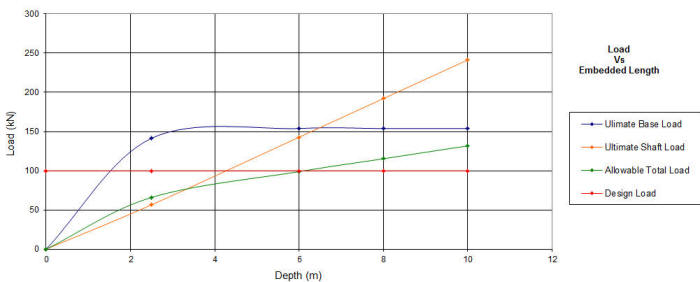

A great many geologists and geotechnical engineers alike have written tens of books on the behavior of piles in soils and rock. To explain very basically, there are various methods of supporting a building on piles. Two of which as follows;

A long pile sunk in to London clay will create most of its load capacity via the "grip" of the clay on the wall of the pile.

|

A pile in an estuarine environment may see several meters of soup

like silts or muds with no bearing capacity. However, there may be

bedrock suitable for an end bearings below this soup like layer. In this

instance the skin of pile has little friction on the soup like upper

strata instead transferring load to bedrock below. For more information visit UWE's website. The image to the left shows a hypothetical end bearing pile situation. These may used in areas with thick silt or peat layers over bed rock. Of course sometimes the bedrock is so deep that to provide foundations for a heavy structure can become unfeasible. |

Eurocode 7 is a very thorough (169 page) standard for geotechnical design. EN 1997-1:2004 (Eurocode 7) is an extremely useful document when used as a guide to required report contents. From the out set it defines design requirements:

EN 1997-1:2004 (Eurocode 7) also suggests that it should be considered that knowledge of the ground conditions depends on the extent and quality of the geotechnical investigations. Such knowledge and the control of workmanship are usually more significant to fulfilling the fundamental requirements than is precision in the calculation models and partial factors. Which is good advice, which is why we would always insist that a site engineer overseas all sampling and in-situ testing work.

EN 1997-1:2004 (Eurocode 7) is a European code, and each member state, including the UK may make it own additions to the code where it is left open to interpretation. To that end it is important to read the UK National Annex to EN 1997-1:2004 (Eurocode 7), as it contains supplementary information. One example of such information included within the UK National Annex to EN 1997-1:2004 might be the Partial Resistance Factors that are included for various foundation types etc.

This Standard sets out the procedures to be followed and certificates to be used during the process of planning and reporting of all Geotechnical Works carried out on highways under the jurisdiction of the relevant Overseeing Organisation to ensure that the Geotechnical Risk is correctly managed.

The management of geotechnical risk is broken down in to various, stages. Desk Based, Intrusive and Design, there are also "Feed Back" reports which seek to verify the scheme successful completion.

This standard includes example report layouts, and sets out minimum content for the geotechnical cetificate.

A geotechnical engineering report assembled in line with

"We certify that the Reports*, Design Data*, Drawings* or Documents* for the Geotechnical Activities listed below have been prepared by us with reasonable professional skill, care and diligence, and that in our opinion:

The certificate should list any departures from standards, and also list all of the documents i.e. drawings upon which the the reports scope was based.

Southwest Environmental can issue a geotechnical certificate, as part of a full geotechnical design report.

There are various geological units that run southwest to north east across the UK, that are naturally sulfurous, and as such can create "unpleasant" or aggressive conditions for buried building elements such as concretes, grouts and structural steel. For further information please see our Aggressive Ground page.

Cavities can be a real problem in areas which have been subject to

mining in the past or where the rocks dissolve readily in water

(dissolution).

Cavities can be a real problem in areas which have been subject to

mining in the past or where the rocks dissolve readily in water

(dissolution).

It is often the case that cavities are searched for using ground probing

radar (GPR) this allows quick coverage of large areas, and can pin point

features which may cause complications.

It is possible to highlight risk from cavities in a

Desktop Study, but this type of qualitative assessment often

generates more questions than it answer.

Differential settlement is when ground condition may promote one

side of a structure to settle "differently" to the other side. This is

more common when there is an interface between two lithographical units,

whether they be natural or man made.

Differential settlement is when ground condition may promote one

side of a structure to settle "differently" to the other side. This is

more common when there is an interface between two lithographical units,

whether they be natural or man made.

When backfilling quarries for example, the infill

material will be softer and settle more than the surrounding natural

ground. Careful mapping is required to avoid zones that may experience

differential settlement, or you may end up with a wonky structure.

Differential settlement can also occur when you build over the boundary

between two geological units. This is quite difficult to achieve with

out a relatively large structure. An example here might be a large

industrial building which requires a huge expanse of flat concrete floor

over a large area.

Finally just because soils on sight have a uniform strength does not

mean they will settle uniformly. Unfortunately we often rely on SPT

correlations to derive a settlement factor, so force a relationship

between settlement and strength.

Geotechnical Engineers Bristol

Geotechnical Engineers Exeter

Geotechnical Engineer London

S.D. Content

Geotechnical Engineers

Bristol - 01173 270 092

Exeter - 01398 331 258

London - 02076 920 670